Processing Capacity: 12-2000t/h

Feeding size: 0-300mm

Applied material: calcite, limestone, granite, pebble, dolomite, bluestone, etc.

Application field: sand and stone yard, concrete sand, dry mortar, construction waste, machine-made sand, power plant desulfurization and other industries

Cone crusher can be divided into single cylinder hydraulic cone crusher, compound hydraulic cone crusher (also known as Simmons cone crusher), full hydraulic cone crusher, multi cylinder hydraulic cone crusher, etc. It is widely used in sand and stone yard, concrete sand, dry mortar, construction waste, machine-made sand, power plant desulfurization and other industries. It is used to crush various ores and rocks with medium and above hardness (below 350 MPa), such as calcite, limestone, granite, pebble, dolomite, bluestone, etc.

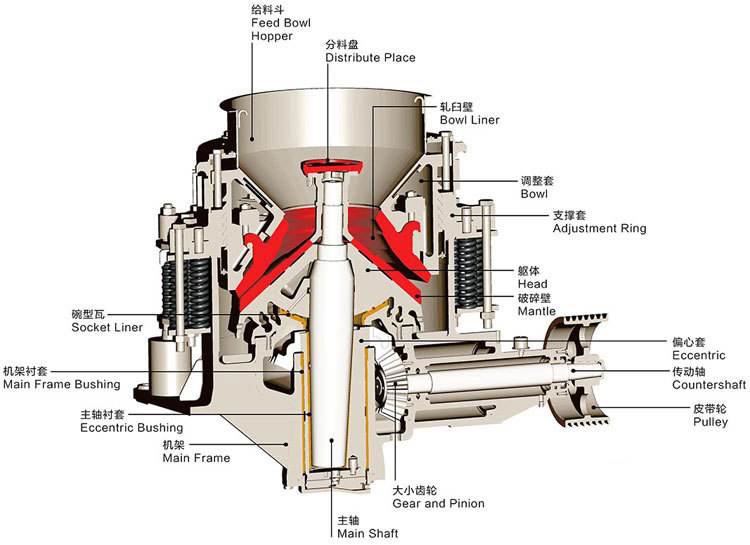

Cone crusher is mainly composed of frame, transmission device, eccentric sleeve, moving cone and fixed cone, adjusting parts, safety device and sealing device.

1.Frame

The frame is the whole structure framework of the equipment. The main frame is composed of the upper frame and the lower frame. The upper frame body is a welding part, and its upper opening is welded with wear-resistant copper plate, and the lower frame body is an integral steel casting. The two are connected by hydraulic cylinder, which play a good supporting and fixing role for other parts of the crusher. The reason why the crusher equipment can be well coordinated depends on the support of the power rack. There are four anchor bolts at the bottom of the frame to fix the frame.

2. Transmission device

The components of the transmission device are mainly densely installed in the transmission axle box. The drive shaft bearings of cone crusher are mainly rolling and sliding bearings. If the quality is good, combined with good assembly and lubrication system, the sliding bearing has high efficiency, long life and convenient maintenance. One end of the transmission axle box is connected with the motor through belt and pulley. After internal power adjustment, the power is transferred from the small bevel gear at the other end to the large bevel gear on the eccentric shaft sleeve to drive the equipment to run.

3. Eccentric shaft sleeve

The eccentric sleeve part is mainly composed of eccentric sleeve forged with cast steel, large bevel gear and conical bush. The bushing is installed inside, and the big bevel gear and thrust bearing are installed in the lower part. In addition, the eccentric shaft sleeve is also equipped with a counterweight component fixed by bolts, and a wear-resistant protection lining plate is installed inside.

4. Moving cone and fixed cone

The moving cone part is composed of the drive body and the main shaft assembled by hot pressing. Wear resistant manganese steel liner is usually installed on its surface to prevent serious wear of moving cone. A bushing is installed inside the moving cone. The feeding hopper is installed on the upper part of the fixed cone, the wear-resistant lining plate of high manganese steel is installed inside, and the trapezoidal thread matching with the adjusting ring is outside.

5. Adjusting parts

The adjusting ring part of cone crusher can also be regarded as a fixed cone with serrated thread on the surface. The adjusting ring is connected with the bearing ring through its external tooth shaped thread support, so that the height of the fixed cone can be changed when the adjusting ring is rotated, so as to realize the adjustment of the size of the ore discharge port of the crusher. The outer sleeve of the adjusting ring has a locking cap with a locking cylinder. The clearance of the serrated thread connection can be eliminated by locking the cylinder, so that the two threads are in contact with each other. In this way, when the cone crushing material is in the normal range, the contact surface between the adjusting ring and the supporting ring is in close contact with no gap in the direction of impact force, so the impact effect will not occur.

6. Safety device

The spring safety system of the cone crusher is an overload protection device. A spring group with buffer function is installed along the circumference of the supporting ring. The supporting ring is pressed on the frame with the upper conical surface of the frame. In this way, even if there are foreign matters, iron block will not harm the machine. The use of the spring safety device greatly reduces the downtime.

7. Sealing device

The internal structure of cone crusher has good sealing performance. Dry oil or water can be used to isolate stone powder from lubrication, ensure reliable operation, and effectively protect equipment from dust and other small particles.

When the motor is working, the motor rotates around a fixed point through the pulley or coupling, the transmission shaft and the conical part under the forced action of the eccentric sleeve. As a result, the crushing wall of the crushing cone sometimes gets close to and sometimes leaves the surface of the mortar wall fixed on the adjusting sleeve, so that the ore is continuously impacted, squeezed and bent in the crushing chamber to realize the ore crushing.

1. Large crushing ratio

The combination of high performance crushing cavity and high crushing frequency greatly improves the processing capacity of cone crusher;

2. Laminated crushing, good grain shape

Using the principle of interlaminar crushing, the crushing products are mostly cubic structure, which can reduce the needle and flake materials to a greater extent.

3. The structure is simple and easy to maintain

The cone crusher has the advantages of simple structure, easy operation and maintenance, convenient and quick adjustment of discharge port, saving time and effort in maintenance, especially the lining plate is easy to be replaced quickly, which reduces the downtime.

4. Hydraulic overload protection, do not damage the equipment

The spring safety system of cone crusher can not easily damage the equipment when the non breakable foreign matter passes through the crushing chamber or the machine is overloaded for some reason. When the foreign matter is discharged from the crushing chamber of the cone crusher, if the foreign matter is stuck in the ore discharge mouth, the cavity cleaning system is used to make the ore discharge to the crushing chamber of the cone crusher; under the action of the spring, the ore discharge port automatically resets, and the equipment can resume normal operation.

5. Different types and various choices

Cone crusher series crusher is divided into three types: coarse crushing cone crusher, medium crushing cone crusher and fine crushing cone crusher, which can be purchased according to different needs of users.

Our sales team is available to respond to any queries you might have on ShuGuang. Get in touch using the details below:

Address No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China

0086-371-67666660