Processing Capacity: 0.3-16t/h

Feeding size: ≤30mm

Applied material: barite mining feldspar,limestone,quartz stone,marble,calcite,barite,tale,gypsum powder,kaolin,bentonite,quartz sand,gold powder,etc.

Application field: building materials,chemical industry,metallurgy,pharmaceuticals,abrasives,etc.

Raymond mill, also known as Raymond roller mill and Raymond grinding mill, is a kind of grinding equipment. The equipment adopts the advanced technology and structure of similar products, and is updated and improved on the basis of Raymond mill in the same industry. The mill has high efficiency, low power consumption, small floor area and small one-time investment. The grinding roller is tightly rolled on the grinding ring under the action of centrifugal force. Therefore, when the grinding roller and grinding ring are worn to a certain thickness, the output and fineness of the finished product will not be affected, and the replacement cycle of the grinding roller and grinding ring is long, thereby eliminating the shortcoming of the short replacement cycle of the wearing parts of the centrifugal crusher.

Raymond mill is widely used in more than 280 kinds of non flammable and explosive mineral, chemical and construction industries, such as barite, calcite, potash feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, thermal insulation materials, etc. the Mohr hardness is no more than 9.3, and the humidity is below 6%. In the process of high and fine milling, the size of finished product of R-Raymond mill can be adjusted arbitrarily within the range of 80-325 mesh, and some materials can reach 2000 mesh when they are high.

1. High structure and technology: the transmission device of the main engine adopts sealed gear box and belt wheel, and the main shaft and plum blossom frame are reformed in favor of stability to make its operation more stable and reliable.

2. Durable parts: the structure of the grinding roller has been updated, so that the grinding roller and the grinding roller shaft can complement each other, improve the durability of the grinding roller and reduce the loss of wear-resistant parts.

3. Good grain size of finished product: the particle size of the finished product grinded by the equipment can be adjusted arbitrarily in the range of 80-325 mesh. When some materials are high, it can reach 600 mesh.

4. Safety and stability: there are explosion-proof measures on the upper part of the body of Raymond mill, which can greatly avoid the accidental injury caused by the explosion of Raymond mill.

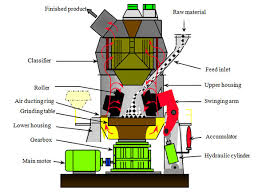

The structure of Raymond roller mill is reasonable and scientific. It is mainly composed of main engine, analyzer, blower, cyclone separator, pipeline device and motor. The main engine is composed of frame, inlet volute, blade, grinding roller, grinding ring and cover. Raymond machine with jaw crusher, bucket elevator, electromagnetic vibration feeder, electric control cabinet, etc., can be combined into a complete grinding production line, which can easily meet the requirements of 80-325 mesh for limestone, calcite, barite, bentonite and other materials.

1. Raymond grinding process: when working, the materials to be crushed are added into the machine from the feeding hopper on the side of the machine cover. Relying on the grinding roller device suspended on the plum blossom frame of the main engine, it rotates around the vertical axis and rotates itself. Due to the centrifugal force during the rotation, the grinding roller swings outward and presses tightly on the grinding ring, so that the shovel picks up the material and sends it between the grinding roller and the grinding ring.The purpose of crushing materials is achieved by dynamic rolling.

2. Air separation process of Raymond Mill: after grinding materials, the fan will blow the air into the main shell and blow up the powder. The fine and coarse materials will fall into the grinding room for regrinding. The fineness that meets the specification will enter the cyclone collector with the air flow, and then it will be discharged through the powder outlet. The air flow is returned to the fan by the return air pipe at the upper end of the large cyclone collector. The air path is circular and flows under negative pressure. The increased air volume of the circulating air path is discharged through the waste gas pipe between the fan and the main engine, and then enters the small cyclone collector for purification treatment.

| Model | 6R4525 | 5R4119 | 4R3216 | 3R3015 | 3R2715 | 3R2615 | 3R2115 | 3R1510 |

| Feed size(mm) | ≤30 | ≤25 | ≤25 | ≤25 | ≤20 | ≤20 | ≤15 | ≤15 |

| Finished particle size(mm) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

| Speed of central shaft(r/min) | 82 | 105 | 130 | 160 | 160 | 160 | 180 | 280 |

| Grinding ring inner diameter(mm) | 1620 | 1270 | 970 | 865 | 830 | 780 | 650 | 495 |

| Grinding roller diameter(mm) | 450 | 410 | 320 | 300 | 270 | 260 | 210 | 150 |

| Grinding roller height(mm) | 250 | 190 | 160 | 160 | 150 | 150 | 150 | 100 |

| Host motor |

y315m-4-132 | y280s-4-75 | y225s-4-37 | y225m-8-22/30 | y225m-8-22 | y225s-8-18.5 |

y200l-8-15 |

y160m-6-7.5 |

| Fan motor | y315m-4-132 | y250m-4-75 | y200l-4-37 | y180m-4-22 | y160l-4-18.5 | y160l-4-15 | y160m-4-11 | y132s-2-5.5 |

| Analyzer motor | y160m-4-11 | yc200-4b-7.5 | yc120-4a-5.5 | y112m-6-2.2 | y112m-6-2.2 | y112m-6-2.2 | y112m-6-2.2 | y90l-6-1.1 |

The price of Raymond mill varies according to the model and output size. The shuguang machine manufacturer has been specialized in manufacturing milling equipment for nearly 30 years, and has rich production technology and management experience. Because shuguang Raymond mill is sold in many regions, the equipment is directly sold to users, and the price is more favorable than that of middlemen , you can tell us the model and quantity of Raymond Mill you need by leaving a message. If you have any other questions and needs, you can also visit the shuguang factory for on-site visit.

Zhengzhou Suguang Heavy Machinery is a manufacturer of "milling equipment". The Raymond mill machine produced is complete in models, the manufacturer has good service, and the price is affordable. Suguang Heavy Machinery welcomes customers from all walks of life to come to the factory for on-site inspection and free trial machine.

Our sales team is available to respond to any queries you might have on ShuGuang. Get in touch using the details below:

Address No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China

0086-371-67666660